MEPC is renowned for its capability to undertake Blast Furnace Revamping Projects by providing the very best revamping solution that incorporates state-of-art technology and optimization of the existing facilities – all in the least possible time.

The fundamental principles and philosophy of BF revamping :

- Adoption of state-of-the-art technology and use of advanced equipment to achieve the aims of good quality, high productivity, low consumption and least cost after commissioning of the BF.

- Strict implementation of the design criterion and ensuring safety during operation.

- Strong emphasis on Design to ensure protection of the environment, fire control and industrial sanitation. Design also stresses on waste treatment and meet local regulations.

- Strict adherence to the ISO-9001:2000 Quality System and Standard Procedures to ensure top quality in Design.

State-of-the-art technology and improvements for BF revamping include but are not limited to:

- Long Campaign Life: in excess of 10 years for Mini-Blast Furnaces and more than 15 years for Furnaces of over 1000m3. Use of Ceramic cups and Carbon blocks for Under-Hearth and Hearth with a reliable Cooling system that ensures a long service life.

- State-of-the-art Bell-Less Top: reliable sealing and flexible distribution, bring about sound charging and furnace top gas system.

- Thin lining of the BF proper and closed-circuit water softening process.

- Carbon-ceramic cup for BF hearth and bottom, and combined bricks for tuyere and main bustle.

- Tangential Top-Fired Stove with Ceramic Burners as also Combustion Air & BF Gas Double Pre-heating System: easily achieve 1150-1200 degrees Centigrade blast temperature. Oxygen enrichment rate: 3-5%.

- Dry-type Gas Cleaning Plant: no water consumption, no emission of impurities, high gas temperature, high gas quality, power saver, optimized land use, low investment, etc.

- Pulverized Coal Injection (PCI): injection rate up to 200kg/t hot metal with reliable safety measures.

- Top Pressure Recovery Turbine (TRT): best described as "MONEY PRINTER", utilizing BF gas pressure to generate power.

- Screw Conveyor-type Slag Granulation Plant (latest generation of slag granulation technology): a high automation level slag granulation technology available now, environmental friendly, energy efficient, least construction area, less investment, easy operation and minimal maintenance.

- Modified automation and instrumentation system incorporated into the existing system.

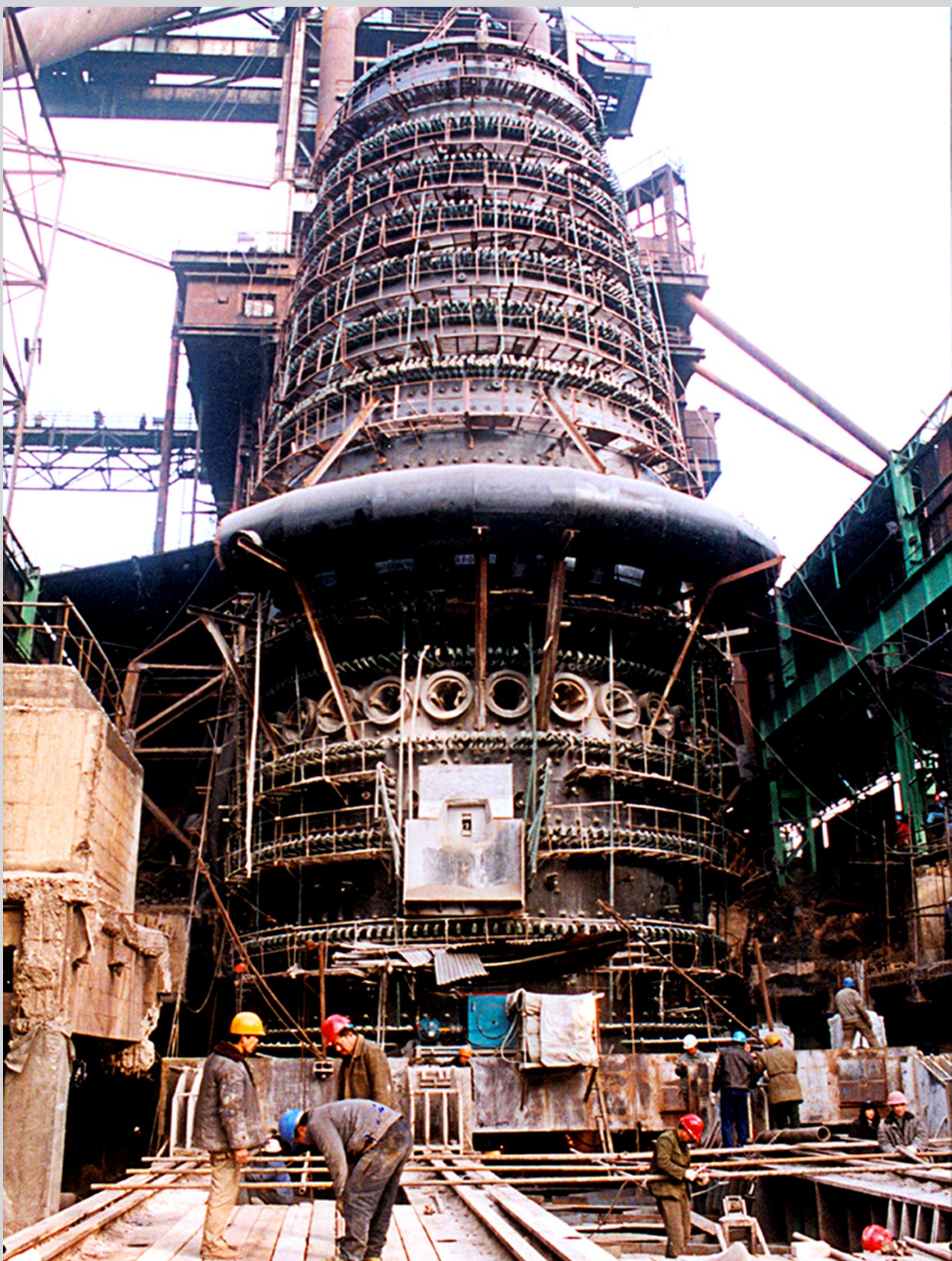

MEPC with Tangshan Iron & Steel Design & Research Institute has undertaken three Blast Furnace revamping projects in China, including upgrading two nos. of 1260 m3 furnaces to 2000 m3 in 2001 and 2003. For these two furnaces, the horizontal and integral-moving technology was used. Rings of the Shell for the new furnace were built adjacent to the old furnace that was in operation. After the main structure of the new furnace was completed, a passage was made in the Cast House to move the new Furnace. Meanwhile, the old furnace was dismantled. Hence, in a mere 42 days shut-down time the new 1260m3 was commissioned. The the shut - down time for second Revamping project was only 39 days . The least time shut - down time has created a history in both, moving the New Furnace and in its completion. The latest Revamping project has been done on a 2560m3 BF that has been upgraded to 3400m3 with a shut - down time of only 40 days.

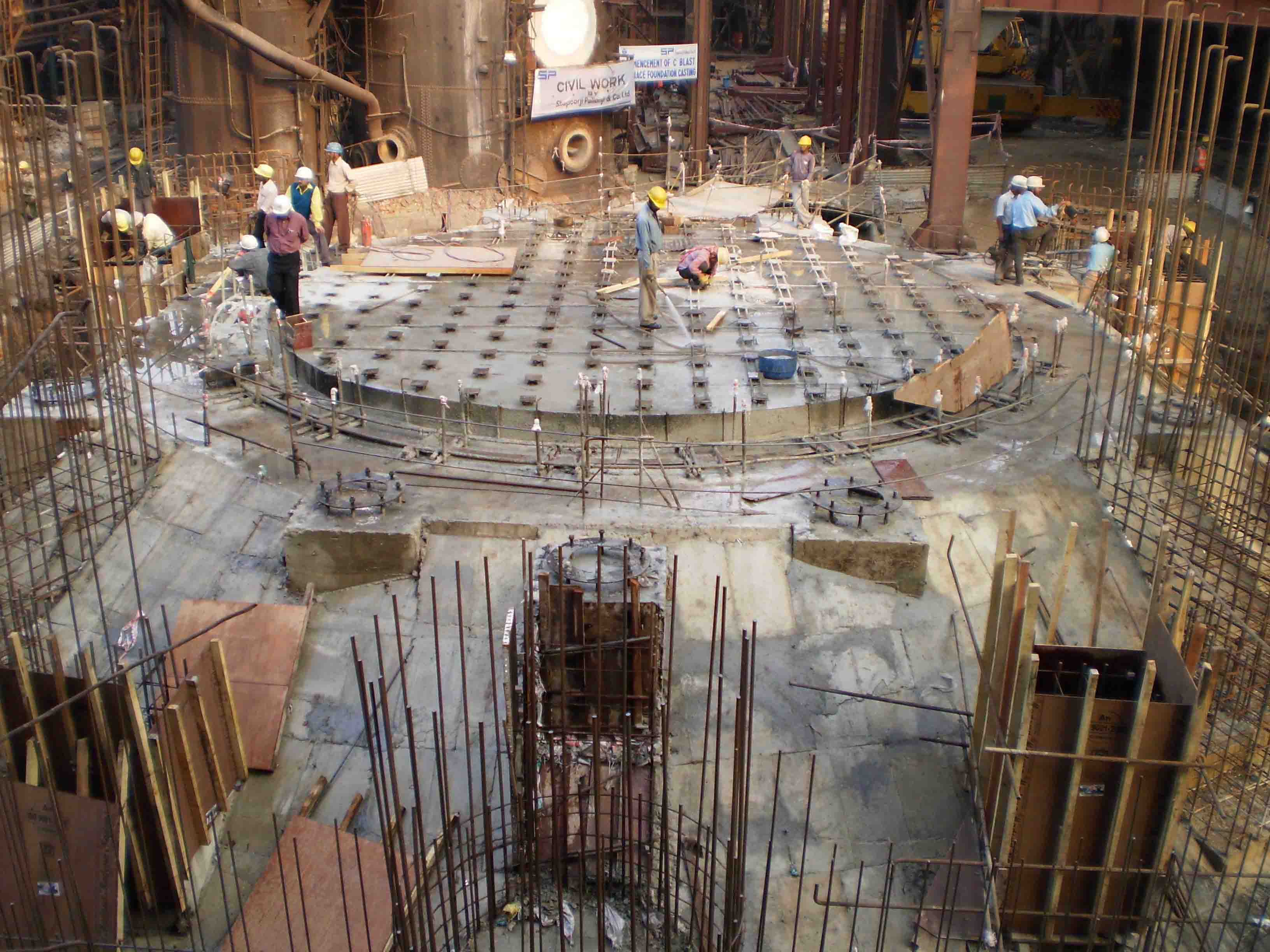

In India,TATA STEEL awarded MEPC to revamp its C BF (719m3). After a careful study of the furnace foundation and its auxiliary facilities, MEPC has proposed to increase the volume to 1080m3. MEPC has provided core equipment and Indian standard civil drawings and structure fabrication drawings of furnace shell, tower structure and skip bridge, which enabled TATA STEEL to fabricate locally and save great cost. The revamped blast furnace was successfully commissioned on Sep.22nd 2009 and within ten days after commissioning, it achieved production of 2350 tons/day and exceeded the designed production. This project has won MEPC great reputation in TATA STEEL.

|

|

| Cast House Construction | Furnace Foundation |

|

|

| Furnace proper Horizontal and Integral Moving in 1260 M3 BF Revamping Project | Furnace proper Horizontal and Integral Moving in 2560 M3 BF Revamping Project |

| TATA C BF View After Revamping | |

Fax:+86-10-8511 3977

Copyright (c) 2009 MEPC Corporation.All Rights Reserved 京ICP备05011865号