Phone:+86-10-6528 9916

Fax:+86-10-8511 3977

Copyright (c) 2009 MEPC Corporation.All Rights Reserved 京ICP备05011865号

OXIDIZED PELLETIZING PLANT

GRATE-KILN TECHNOLOGY AND SHAFT FURNACE TECHNOLOGY

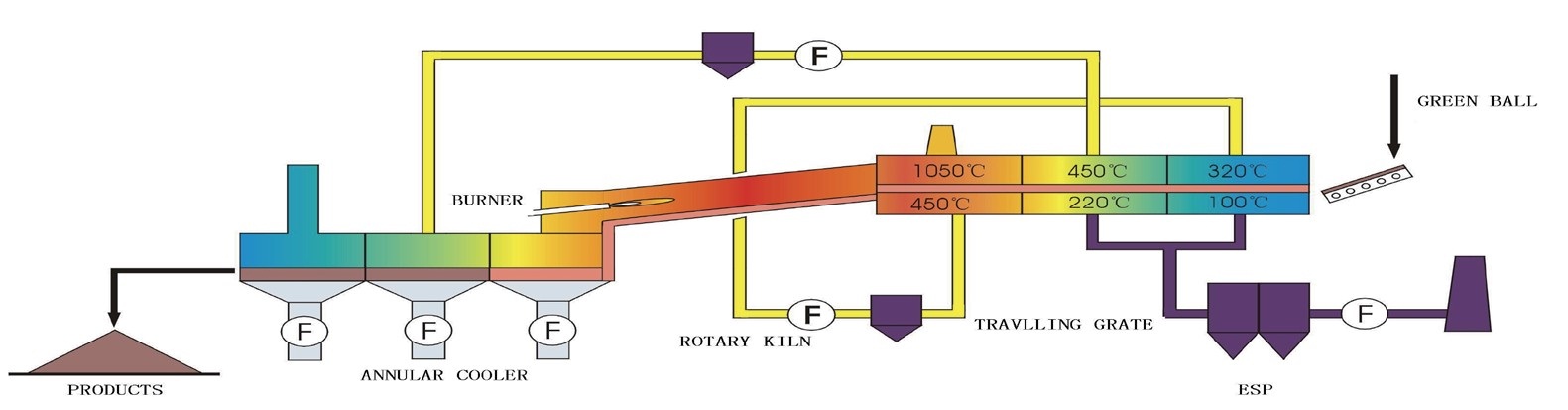

I - GRATE-KILN TECHNOLOGY

1. High quality of pellet and good uniformity;

2. Both magnetite and hematite iron ore concentrate can be used as raw material.

3. Good adaptability of different fuel, such as pulverized coal, mixed gas of BF/coke oven gas, converter gas,natural gas, furnace oil and so on.

4. Pollution free and clean production environment;

5. Suitable for various capacity from 0.3 million tons up to 3.0 million tons per year

6. Product can be used as BF burden and making DRI.

Process flow diagram

|

THE QUALITY STANDARD OF ACID PELLET

| Chemical Composition (%) | |||||

| TFe | FeO | SiO2 | Al2O3 | S | P |

| >63 | ≤1.0 | S2.0 – 3.0 | 2.0 – 3.0 | 0.006(max.) | 0.08 ( max.) |

| Physical Properties | |||||

| Compression Strength(N/p) | Tumbling Index (+6.3mm) | Abrasion Inde(-0.5mm) | Bulk density(t/m ) | Expansion ratio(%) | |

| 2200 | >95% | <4.0% | 2.1 | >18% | |

II –TECHNOLOGY OF SHAFT FURNACE

|

1. Initial investment is low.

2. High quality and lower operation cost

3. Magnetite or mix with less than 30% hematite can be used as feed material.

|

4. BF gas, coke oven gas and producer gas can be used as fuel for induration of pellet.

5. Waste heat is fully utilized and energy can be saved.

6. Suitable for various capacity from 30,000 ton up to 600,000 tons per year.

|

|

|

网站合作:济南上门按摩